Meredith has authored double declining balance depreciation method 200+ blog posts, 20+ merchant case studies, and 10+ eBooks for ShipBob. She has also written content for Arka, Adquadrant, Okendo, and Tydo, establishing herself as a thought leader in logistics and fulfillment strategy. ‘Finished goods’ inventory are items that have been completed by the manufacturer and are ready to be sold for revenue. Understanding WIP inventory can be challenging, especially since it consists of many moving parts during the production process.

Understanding In Process vs. In Progress: Key Differences

The cost of WIP inventory is a bit more complex than determining the value of finished goods, as there are many more moving parts. Before attempting to calculate your current WIP inventory value, here are some terms you will need to know first. Effective implementation of these best practices ensures that WIP is managed efficiently, leading to improved quality, reduced costs, and enhanced customer satisfaction. Various stakeholders in the quality management ecosystem benefit from understanding and effectively managing WIP. Taking time to classify WIP inventory in a warehouse waiting to be assembled might seem tedious, but it’s crucial for monitoring and improving your supply chain and inventory control.

Low WIP Levels

Work in progress refers to partially-completed goods that are still in the production process. These items may currently be undergoing transformation in the production process, or they may be waiting in queue in front of a production workstation. It work in process tends to refer to processes that require a significant amount of time to complete. By tracking WIP carefully, companies can understand exactly how much capital is tied up and make smarter decisions about cash flow and purchasing. The main purpose of work in progress is to improve efficiency and reduce costs by streamlining the manufacturing and shipping processes. Continuous learning and adaptation are essential in the dynamic quality management landscape.

- This keeps work still needing completion visible so everyone knows what is happening, and interruptions are eliminated which allows people to plan their next steps before other potential interruptions.

- WIP stands for “work in progress” and refers to any partially complete inventory not yet ready to be sold to customers.

- This term is also aligned with related expressions, such as a work that is ‘making progress’.

- WIP inventory information gives you an idea of how your raw materials, labor, and facilities are being used.

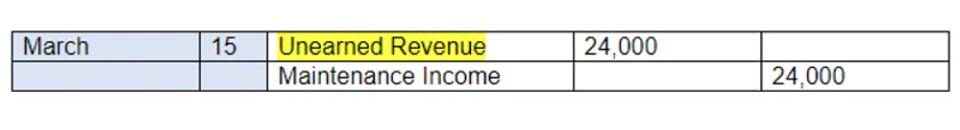

- If you don’t adjust for these changes, your reported cost of goods sold may be off.

- You can think of WIP inventory as all inventory that has not yet reached the finished product inventory but is not raw materials.

How to Calculate Work in Process Inventory? (Formula)

- Since ‘in progress’ is more commonly used and is more familiar to readers, it’s a good idea to use this phrase in most situations.

- It sits between raw materials and finished goods, reflecting the stage of production.

- Holding too much WIP ties up working capital in unfinished goods, drives up storage costs, and limits warehouse space that could otherwise be used for revenue-generating finished products.

- On the other hand, it could also be a sign of under-used production capacity.

In this case, work-in-process includes the accumulated cost of the asset, which will continue to increase until the structure is declared complete. At that point, the balance in the work-in-process account is recognized as a building fixed asset, and is shifted into the building fixed assets account. It is generally considered a manufacturing best practice to minimize the amount of work-in-process in the production area, since too much of it interferes with the process flow. Further, production expediters may be used to force certain key jobs through the pile of work-in-process jobs, which throws the production system into an even greater muddle.

Conclusion: Embracing the Subtleties of English Phrasing

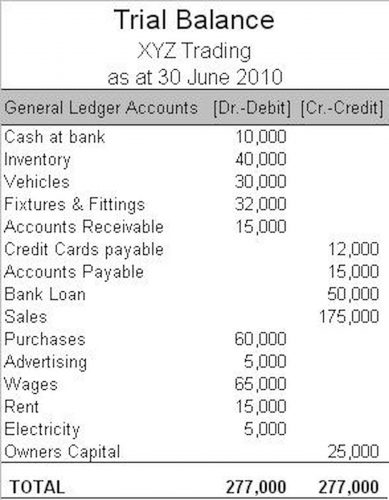

Since these items are neither raw https://www.bookstime.com/ materials nor finished products, they must be recorded separately on the company’s balance sheet under current assets. Accurate reporting of WIP inventory helps businesses track production costs, manage resources efficiently, and maintain precise financial records. Firstly, the term ‘work in process’ often denotes partially completed goods that are standard manufactured items. They are typically converted from materials to finished products within a short period.